Panasonic Placement Machine NPM-DX

Operator:DAIICHI Hits:420

2026-02-07 21:25:06

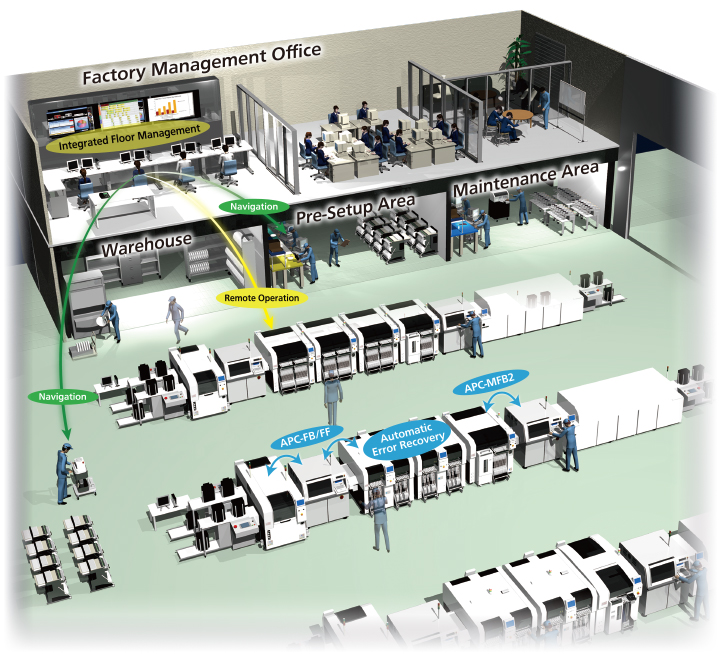

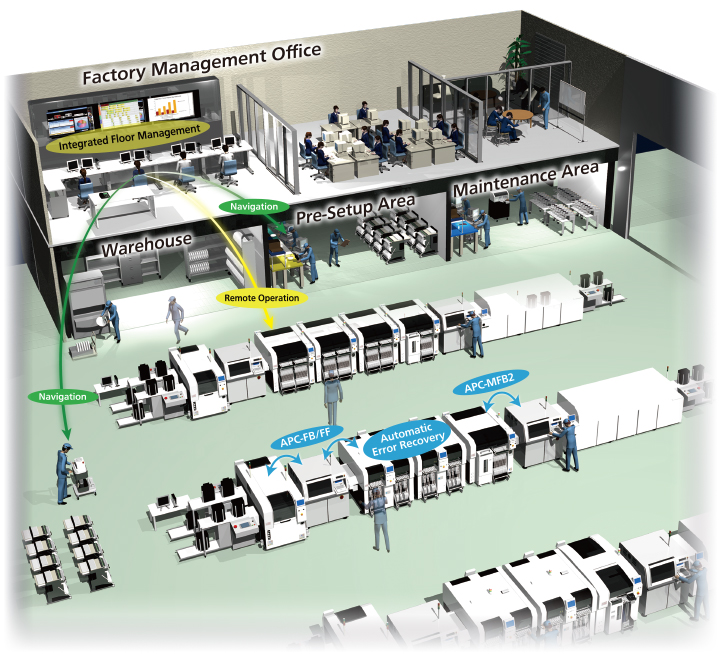

Panasonic's next-generation mounting manufacturing (X series) concept "smart manufacturing"

Automation and labor saving of the assembly workshop, increase production line capacity and quality, and reduce costs

Autonomous function to achieve stable operation-Autonomous production line control

APC system, automatic recovery options

Labor saving and operation rate improvement-centralized control of

workshop management system, remote operation options

Suppress the unevenness of manual work-navigation, automated small product

feeder preparation navigation, component supply navigation, automated small product

|

Model name |

NPM-DX

|

Substrate size (mm)

*When choosing a long conveyor belt

|

Monorail |

L 50 × W 50 ~ L 510 × W 590 |

|

Dual track |

L 50 × W 50 ~ L 510 × W 300 |

Substrate replacement time

*When selecting a short specification conveyor belt

|

2.1 s (L 275 mm or less)

4.8 s (L 275 mm more than ~ L 460 mm or less) *Different depending on the board specifications |

|

power supply |

Three-phase AC 200, 220, 380, 400, 420, 480 V 5.0 kVA |

|

Air pressure source *1 |

Min.0.5 MPa, 200 L/min (ANR) |

|

Equipment size (mm) |

W 1 665 *2 × D 2 570 *3 × H 1 444 *4 |

|

weight |

3 600 kg (Main body only: Varies depending on the configuration of options.) |

|

|

Placement head |

Lightweight 16-nozzle placement head V2

(per placement head) |

Lightweight 8-nozzle placement head

(per placement head) |

4 nozzle placement head

(per placement head) |

|

the fastest speed |

46 200 cph

(0.078 s/chip) |

24 000 cph

(0.150 s/chip) |

8 500 cph

(0.424 s/chip)

8 000 cph

(0.450 s/QFP) |

|

Placement accuracy (Cpk≧1) |

± 25 μm/square chip |

± 25 μm/square chip

± 40 μm/QFP □ 12 mm or less

± 25 μm/QFP □ 12 mm ~ □ 32 mm |

± 20 μm/QFP |

|

Component size (mm) |

0201 chip *5*6 / 03015 chip *5

0402 chip*5 ~ L 6 × W 6 × T 3 |

0402 chip *5 ~L 45 × W 45 or L 100 × W 40 × T 12 |

0603 chip ~ L 120 × W 90 or L 150 × W 25 × T 30 |

|

Component supply |

Taping |

Editing width: 4/8/12/16/24/32/44/56 mm |

Editing width: 4 ~56 / 72/88/104 mm |

|

4. 8 mm tape: Max. 136 varieties |

|

Rod-shaped |

Max. 32 varieties (single rod feeder) |

|

*1: Main body only

*2: W size is 2 265 mm when mounting with extended conveyor belts (300 mm) on both sides

*3: D size when mounting an exchange trolley

*4: Excluding displays, signal towers, and ceiling fan covers.

*5: 0201/03015/0402 components require special nozzles and special tape feeders.

*6: 0201 component placement is an option. (Conditions specified by our company)

*The mounting speed and accuracy etc. will vary depending on the conditions.

*Please refer to "Specification Manual" for details.

第一实业有限公司,翻新(二手)SMT/AI设备,全新设备代理,维修保养服务及配件销售, SMT设备租赁服务, SMT设备收购松下高速贴片机:CM602,CM402,HT122,MSR,CM88S,MSH3,MV2VB,MV2F,松下多功能贴片机:DT401,BM123,BM221,CM120,CM20F,MSF,MPAV2B,MPAG3,MPAV2,富士高速贴片机:NXT ,XP143,XP142,CP842,CP742,CP732,CP643,CP6,富士多功能贴片机:NXT,XP243,XP241,QP341,QP242,AI机器:JVK3,JVK2,JVK,AVK3,AVK2B,AVK2,AVK,AVF,RHS2B,RHS2,RHS,RH3,RH2,RH6B,RH6,公司简介:"第一实业"-电子业设备的业界领导者,于1997年成立之企业,经过27年之发展和成长,积累了丰富的管理、市场、生产、技术和工艺经验,向客户提供SMT/AI设备完全解决方案, 业务包括翻新SMT/AI设备,全新设备代理,维修保养服务及配件销售,设备租赁服务,设备收购等。发展至今,客户遍布全中国及东南亚,已成为亚洲第一翻新电子设备供应商。

我们以香港总部为基础,拥有2间厂房,在东莞及苏州分别有设备翻新工厂,供应各种SMT/AI系列设备及提供专业技术服务。现时我们设备製造之员工人数达150多人,其中资深工程师20多人,另外,在东莞的EMS工厂,拥有多条先进高速生产线,可为客户提供EMS/OEM电子生产服务。

多年以来,以"诚信第一,品质第一,服务第一,方为第一"的信念,致力為客户提供最优质,及完善的客户服务,协助提高生产力、竞争力及增加盈利。此外,我们已通过ISO9001认证,为中国的二手翻新设备行业中首家通过ISO认证的工厂, 生產过程的质量,调试,检测均受到严格品质管理控制。

我们坚持以"诚信、创新、团结、高效"一直作為服务广大客户的精神, 做好准备目标成為世界一流水準之成功企业。

办公楼 办公环境 会议室 设备收购:海外检验机器-装箱运输-香港仓库-入厂检验-设备档案、检验记录;工程服务:生产、技术工程顾问服务;设备安装(搬厂、重组);员工操作培训;紧急修理;设备维护、保养及图片.友情链接: 热销机型: AVK2B、AVK3、AV131、RL131、RG131、JV131、RHS2、RSH2B,热销机型: NPM、NPM-D、CM602、CM402、CM400、CM401、CM201、CM202、DT401 、CM212、CM20F、BM123、BM221、CM301、MSF,热销机型: NXT M3S、XP142、XP143、XP242、XP243,